+++ BMW voiced its firm confidence over long-term development prospects of the Chinese market, following the opening of a new plant in Shenyang, capital city of Northeast China’s Liaoning province, on Thursday. BMW Brilliance Automotive named the new plant Lydia, which marks an upgrade for the large-scale production base in the region. This is BMW’s third automobile plant in China. It is designed to mainly produce battery-powered electric cars, including the all-new i3, a midsize sport sedan that BMW designs exclusively for the Chinese market. Construction of the Lydia plant started in 2020. BMW invested 15 billion yuan ($2.23 billion), its largest investment in China in the past 19 years. The plant is expected to increase the annual output of BMW Brilliance’s Shenyang production base to 830.000 vehicles from 700.000 units in 2021. “The new plant can be transformed to fully produce electric vehicles on its flexible manufacturing lines, according to market demand”, said Jochen Goller, president and CEO of BMW Group Region China. “Together with the newly upgraded Dadong plant, Lydia will play an important role in accelerating China’s electrification of its auto industry”, he said. Since 2010, BMW Brilliance has invested around 83 billion yuan in Shenyang to build a production system integrating research and development, procurement, and vehicle production, making Shenyang the largest production base of BMW in the world. “The years of in-depth cooperation between Shenyang and BMW have made us deeply realize that the best relationship between a city and an enterprise is common growth and creating the future together”, said Wang Xinwei, Party secretary of Shenyang. “We expect that BMW will accelerate the electrification of the auto industry and produce more excellent products with cutting-edge technologies and exquisite workmanship”. In 2021, over 3.5 million new energy vehicles were sold in China, the largest number in the world, according to the China Association of Automobile Manufacturers. Local governments also promoted policies to support purchases of NEVs. The State Council executive meeting on Wednesday noted that the extension of the tax exemption policy for NEV purchases, which is to expire by the end of the year, will be explored in light of current conditions. Implementation of these policies is expected to increase automobile and related sales by about 200 billion yuan this year. Industry insiders said the Lydia plant reflects BMW’s efforts to catch up with the booming EV market in China, which is now dominated by Tesla and Chinese automaker BYD. “The BMW project is a successful example of foreign-funded enterprises in China”, said Li Lecheng, governor of Liaoning. “This year marks the 50th anniversary of the establishment of diplomatic relations between China and Germany. We hope that BMW Group adheres to the localization development strategy, integrates the company into Liaoning’s development, deepens cooperation with Liaoning and makes positive contributions to the healthy and stable development of China-Germany relations”. +++

+++ CHINA ’s automotive industry is speeding up its recovery from the Covid-19 impact as vehicle production in the country has returned to levels seen prior to outbreaks earlier this year. Guo Shougang, a deputy director at the Ministry of Industry and Information Technology, said production has fully returned to normal, with plant activity in May soaring over 50 percent from April. The ministry has helped solve over 6.000 problems in terms of logistics, transport and production resumption since April and automakers have tried their best to minimize Covid effects as well, Guo said. He made the remarks as the MIIT-together with several other ministries-kicked off an annual event on Saturday to promote new energy vehicles in the country’s vast countryside. SAIC Motor, China’s largest automaker by sales, has seen production returning to pre-Covid levels at its 3 plants in Shanghai, which was hard hit in the latest wave of the pandemic. 1 of the 3 plants in the city belongs to SAIC itself, while the others were built with partners Volkswagen and General Motors. Now the 3 plants have a combined daily output of around 13.000 units, SAIC told. From June 1, more than 200.000 vehicles rolled off the assembly line, an increase of more than 30 percent year-on-year. Production at Tesla’s Shanghai plant resumed even earlier. The United States-based electric vehicle maker told China Daily that the plant reached “100 percent” of its capacity in the second week of June. In May, the plant produced 33.544 vehicles, up 212 percent from April. Sales reached 32.165 units, of which 22.340 were exported. In April, Tesla sold only 1.512 units, and none were exported. Tesla said the plant resumed production in late April with help from local authorities, who held meetings to help facilitate the automaker’s work. The rapid recovery shows the “resilience of Chinese manufacturing”, said Tesla. Over 90 percent of components in its Shanghai-made vehicles are made in China, it said. Passenger car sales in the first 2 weeks of June totaled 512.000 units; up 44 percent month-on-month and 14 percent year-on-year, said the China Passenger Car Association. Lu Jiamin, an automotive analyst at Cinda Securities, said auto sales are expected to gain momentum in the coming months because of the trio of resumed vehicle production, pent-up demand earlier this year and financial stimuli from the government. The central government has halved purchase taxes for vehicles priced no more than 300.000 yuan ($44,850) and with engines no larger than 2.0 liters. The lower tax will be in effect until the end of the year. Local authorities have rolled out their plans as well, offering vouchers worth up to thousands of yuan and additional license plates. Cui Dongshu, secretary-general of the CPCA, expects the favorable policies to increase vehicle sales by an additional 2 million units. They are likely to help raise total passenger vehicle sales in China this year to 21 million units, up 4 percent from 2021. +++

+++ CZINGER will follow its ground-breaking, 1.260 hp 21C hypercar (photo) with a new ‘hyper-grand tourer’, to be previewed by a concept in August. The American start-up’s next creation will be a four-door and sit below the £1.5 million Czinger 21C, which will mean a “more attainable” price, owners Kevin and Lukas Czinger told. They added that the GT will still be very exclusive, with just “a few thousand” to be produced. For comparison, the 21C is limited to just 80 cars. The new GT will be unveiled at the uber-exclusive Concours d’Elegance at Pebble Beach next month. “Our next car will be the highest-performing GT car in the world when it is released”, Lukas said. “It will really show the future direction of Czinger”, added Kevin. The GT is expected to get a variation of the 21C’s twin-turbocharged 2.88-litre V8 engine (which is supplemented by 2 motors) but the pair did confirm the new model will be “very different” from its sibling. The car maker, which started out as a technology firm, is also looking to launch “4 or 5” more “unique” cars by 2030, with an SUV and pure-EV models mooted. Lukas said: “As a brand, Czinger is making the most technologically advanced vehicles in the world. But we want to keep Czinger really focused on cutting-edge, high-performance and luxury cars. We don’t ever want to go into hyper-scale and want to stay at producing around 10.000 vehicles per year”. When asked if a Czinger EV could be on the cards in the future, the father and son duo stopped short of confirming plans but said: “For us right now, for hypercars and high-performance sports cars, the strong hybrid configuration was still best for what buyers are looking for when they pay that price point that we offer. “But, I think EV tech, with our portfolio, will come into play when we look to sell at a slightly lower price point in the future”. An SUV model is also “in our thoughts”, Lukas said, adding: “We are considering it and we have some unique ideas for one, but nothing official as of yet”. They did confirm that all future cars will continue to be created using Czinger’s unique manufacturing method of 3D-printing its parts in-house; something it is also doing for “a few OEMs”. +++

+++ DAIHATSU has announced that its special edition Copen mini sports car will hit the market in September to commemorate the 20th anniversary of the model’s launch. The popularity of mini convertibles peaked in the 1990s, but the demand for such models has remained strong due to their compact size and responsive driving performance. Daihatsu will only make 1.000 Copen special edition vehicles, which will have leather seats and a commemorative emblem. The company started accepting orders for the mini sports car on Monday. The price will be announced at a later date. The 2-seat Copen debuted in 2002. The model was discontinued in 2012, but the second-generation model was released in 2014. As of May, Copen’s cumulative sales totaled about 95.000 units. +++

+++ The automobile industry has become one of the most affected by the GLOBAL CHIP SHORTAGE , which started from the end of 2020. This, in turn, is reshaping the automotive landscape in terms of supply chains, technology and industrial planning, experts said. “As the current situation shows, increasing chip production capacity will not immediately solve the supply chain crisis plaguing auto companies”, said Zhu Yulong, an automotive electronics engineer. In view of the time it takes, starting from the construction of an auto chip manufacturing facility to auto chip production and installation, the newly expanded production capacity by some major chipmakers (including Taiwan Semiconductor Manufacturing Company, or TSMC, Infineon and Intel) can only be realized after 2023, according to industry insiders. Xu Daquan, executive vice-president of Bosch China, said in the short term, it does depend on “rushing to purchase”, adding that car production this year will remain constrained by chip shortages. Experts from the China Association of Automobile Manufacturers predict that the chip shortage will be alleviated by the end of 2022, but “a small-scale shortage will be normal” in the future. For car companies that may not be able to get the chips they need, a “sit and wait” attitude is not feasible. So they found workarounds. Some automakers cope with the chip shortage through production cuts and structure optimization. Specifically, some car companies are reallocating production capacity, shifting limited resources to higher-end models with higher profits and best-selling models. There are also some automakers cutting configurations that do not affect safety, but need chips, such as wireless charging, electric lumbar support and digital keys. Ford, a case in point, said it will sell “semi-finished” vehicles that lack some chips for non-safety-critical functions, and promised to send the chips to its dealers after one year. Automakers are also trying to change the traditional supply-chain cooperation model and have begun to seek direct cooperation with chip manufacturers. Their aim is to no longer be over dependent on primary chip purchasers. For example, Chinese new energy vehicle maker BYD is unaffected by the ESP (electronic stability program) shortage, because it produces BSC (brake safety control system) in partnership with Bosch. Since this year, “becoming their own suppliers” is a part of more car companies’ development programs. It will be a trend for automakers to cooperate directly with chip manufacturers in terms of research and development, design and packaging, according to insiders. Tesla, which was affected by the auto chip shortage, has reduced its dependence on top-tier suppliers through rewriting firmware and using alternative chips. The company’s electrical and firmware teams are designing, developing and verifying 19 new micro controllers. Statistics from Susquehanna Financial Group show that in May, chip delivery time reached 27.1 weeks, or more than 6 months; the longest since the tracking data was recorded in 2017. The chip delivery time was around 4 months in May 2021 and 2 months in May 2019, according to the group. Data released by auto industry forecasting firm AFS show as a result of the chip shortage, global auto production had been cut by around 2.23 million units as of June 12. In comparison with the global chip shortage, the global output of auto chips experienced an overall rise during 2017-21. According to semiconductor industry research institute IC Insights, the global yield of auto chips reached 52.42 billion pieces in 2021, it was 36.29 billion in 2017. The exacerbated imbalance between supply and demand has led to the chip shortage, insiders said. Gu Zhijun, a senior automotive industry analyst, said since the middle of 2021, in addition to their normal order, some automakers and primary purchasers like Bosch have placed extra orders with tier-2 auto chip suppliers. They have done this to avoid the problem of misjudging demand like they did in early 2021 and buffer the subsequent chip demand pressure. This, in turn, has made the imbalance between supply and demand more prominent. German chipmaker Infineon Technologies said it had a backlog of orders valued at 37 billion euros in the first 3 months of this year, an increase of 19.4 percent from the fourth quarter of 2021. That’s more than 3 times the company’s 2021 revenue of 11.06 billion euros. +++

+++ LIVAN AUTOMOTIVE , a joint venture between Volvo-owner Geely and Lifan, said that it is planning to launch at least 6 battery-swapping electric models in 3 years. The first model, a compact coupe SUV called Livan 7, will make its premiere later this week at an auto show in Chongqing, where the carmaker is headquartered, and its production will start in 2023. Lou Yuanfa, Livan’s chairman and CEO, said the carmaker is dedicated to battery swapping, which he believes holds the key to the future of the electric vehicle segment. Livan also unveiled its battery-swapping architecture. It consists of a complete vehicle platform, a battery swapping power supply platform, as well as a cloud-based big data platform. The architecture adopts the unified battery that offers 50 kWh to 100 kWh packs. Vice-president Yang Quankai said the battery has been proven to support 2.500 charge-discharge cycles and allow a car to drive for 800.000 kilometers in 8 years. By the end of this year, Livan is expected to have over 200 battery-swapping stations in the country. A number of companies including CATL, Nio and BAIC have been exploring the battery-swapping segment. CATL is planning to open 30 fast battery-swap stations in Xiamen by the end of this year. There were 1.298 battery-swapping stations by the end of 2021 in China, according to statistics from the Ministry of Industry and Information Technology. +++

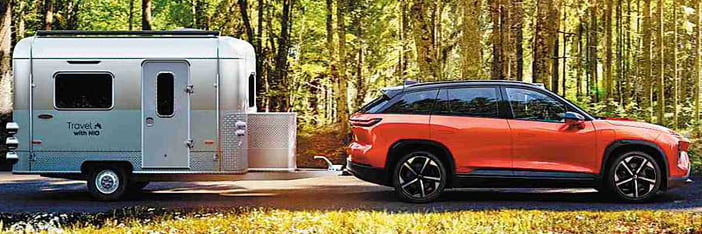

+++ Chinese electric vehicle startup NIO made the world premiere of its ES7 on Wednesday. It is the first SUV based on Nio’s NT2 technology platform and features the carmaker’s latest smart operating system, Banyan. Equipped with a digital cockpit system, PanoCinema, that allows augmented reality and virtual reality, the five-seat SUV aims to provide occupants with an immersive visual and audio experience. Nio cooperated with AR device company Nreal to develop custom glasses that can project an effective 201-inch screen at 6 meters. A Dolby surround sound system and 256-color digital waterfall ambient lighting are also provided. The Nio ES7 adopts a second-generation high-efficiency e-drive platform with a silicon carbide power module and can accelerate from 0-100 kph within 3.9 seconds. The SUV is one of the first passenger vehicles in China certified to tow a big caravan or trailer. An optional electric tow bar has a maximum towing capacity of 2.000 kilograms. The carmaker provides 3 variants of the ES7, at prices starting from 468,000 yuan ($69,685), which are expected to start delivery in late August. +++

+++ The Australian subsidiary of TOYOTA has appealed a Federal Court decision in a class-action case that ordered the Japanese auto giant to compensate Australian customers who purchased faulty Toyota vehicles. Hundreds of thousands of Australian customers who purchased the pickup trucks and other vehicles can apply for compensation from Monday, but payouts, which could reportedly total more than $1.9 billion, may be delayed pending the appeal process. The class action concerned around 264.000 Hilux, Fortuner and Prado vehicles sold in Australia between October 2015 and April 2020. The court in April found that Toyota had misled customers in marketing and selling vehicles with faulty diesel particulate filters, which the court found caused a 17.5 percent reduction in value at the time they were sold. With average compensation payments of $7.500 per vehicle expected, Toyota could be facing total compensation costs of more than $1.9 billion, according to the Australian Broadcasting Corp. Toyota Australia said in a statement that the appeal lodged with the Federal Court on June 10 included “challenges to the factual and legal basis for the award of damages”, arguing that many of the class-action plaintiffs did not experience issues associated with the faulty filters, such as substantial white smoke or a reduction in engine power. Matt McKenzie, a partner at law firm Gilbert & Tobin that conducted the class action against Toyota, told the ABC that there would not be any payouts until the appeal has been decided, a process that could take around a year. +++

+++ An American executive who resigned from TOYOTA after being arrested in Japan in 2015 on suspicion of drug law violations is back at the Japanese automaker, the company said Thursday. Julie Hamp has been hired by Toyota’s North American operations to support its chief executive, Akio Toyoda, and advise the company on global management, sustainability, governance and global media relations. She was arrested on suspicion of importing the prescription painkiller oxycodone, which is tightly controlled in Japan, after arriving in the country to head Toyota’s public relations in 2015. Toyota said her return was not a problem because she was never prosecuted. “Toyota believes the incident in 2015 will not hinder her career going forward”, it said. In 2015, prosecutors said Hamp arranged with her father to have 57 oxycodone pills sent via air mail from the U.S. to a Tokyo hotel. They decided not to pursue charges. Toyota officials repeatedly apologized for the arrest, but Toyoda commented how he wished he could have done more to help Hamp. He also publicly defended her as an important member of the Toyota team. Hamp’s was the first high-profile female promotion at Japan’s top automaker. She joined the company in 2012, overseeing marketing and communications for the Toyota, Lexus and Scion brands in the U.S. She earlier worked for PepsiCo and General Motors. In her latest assignment with Toyota, Hamp will also work on the English version of Toyota’s own media, Toyota Times, according to the maker of the Prius hybrid and Lexus luxury models. +++